ZebraSci’s proprietary silicone inspection technology, FlexHD, is a robust and reliable solution for ensuring proper lubrication and for critical parenteral & injectable applications.

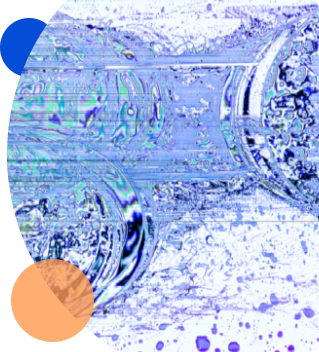

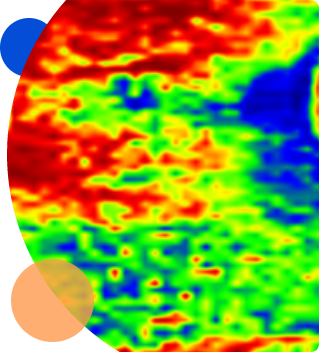

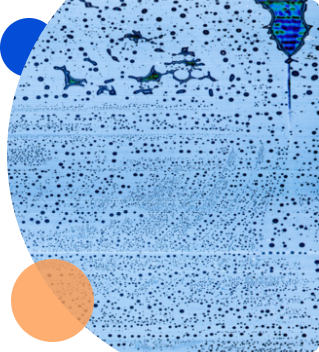

The technology behind our FlexHD silicone characterization platform is used to assess lubricant oil quantity and distribution in primary containers for parenteral applications such as syringes, cartridges, and vials. Our solution provides a 100% non-destructive evaluation of silicone distribution and quantity in a matter of seconds. Using patented technology, the FlexHD allows product development and engineering teams to observe lubrication in real time and make risk-based decisions on container quality.

What’s unique about FlexHD? Our platform easily quantifies silicone within FILLED and EMPTY containers. With a non-destructive technique, we can easily observe silicone mobility over time (stability) or silicone dewetting into the solution due to drug-product interactions.

Silicone Lubrication Characterization is an important step in the product development process. Too much silicone can lead to issues with subvisible particles, while too little silicone may lead to poor performance in a device, resulting in high Break-Loose or glide forces and injection time. At ZebraSci, our team of experts is knowledgeable about the baseline lubrication levels of primary containers from many different container manufacturers and can quickly assist clients with developing a test program to determine the optimum design space.

When selecting primary containers, the importance of silicone characterization should not be overlooked. With an optimized lubrication profile, clients can reduce the risk of problems down the road and prevent unforeseen circumstances that relate to inadequate characterization work. Subvisible particles and free silicone in solution can be well mitigated prior to design verification (DV) to assure a smooth transition into DV and commercial launch. Slow injection time, difficulty with injection, and other device failure modes can be predicted and modeled easily and incorporated into failure mode and effects analysis (FMEA) documentation.

ZebraSci’s experienced engineers have been researching silicone quality and tribology for over a decade. Leverage our experience to help make your next primary container and product development project a success.